China Top PET Shrink Film Manufacturer

Are you tired of dealing with unreliable suppliers and inconsistent quality in your PET shrink film? Look no further! YF Packaging is here to solve all your packaging problems with our top-quality PET shrink film, available at wholesale prices directly from our factory.

Why Choose YF Packaging for Your PET Shrink Film Needs?

Unbeatable Wholesale Prices

Cut out the middleman and save up to 30% on your packaging costs. Our direct-from-manufacturer pricing means more profit for your business.

Consistent High Quality

Say goodbye to product inconsistencies. Our state-of-the-art manufacturing process ensures every roll meets our strict quality standards.

Custom Solutions

Can’t find the perfect fit for your products? We’ll create it for you! Our team of experts will work with you to develop the ideal PET shrink film for your specific needs.

Fast Turnaround

Don’t let packaging delays slow down your business. We offer quick production times, with most orders ready to ship in just 7-10 days.

About Our PET Shrink Film

Our premium PET shrink film is the perfect solution for all your packaging needs. Whether you’re wrapping beverages, bundling products, or creating tamper-evident seals, our film delivers exceptional results every time.

Key Features:

- Crystal Clear Clarity: Showcase your products with film that’s 99.9% transparent.

- Superior Strength: Our film is 25% stronger than standard PVC, reducing tears and breakage.

- Excellent Shrink Properties: Achieve a tight, smooth wrap with our film that shrinks up to 70% in the transverse direction.

- Versatile Temperature Range: Performs well from -40°F to 149°F (-40°C to 65°C).

- FDA Approved: Safe for direct food contact.

Available Sizes and Thicknesses:

- Width: 1″ to 80″ (25mm to 2032mm)

- Thickness: 30 to 150 gauge (7.6 to 38 micron)

Custom sizes available upon request.

Solving Your Packaging Challenges

Problem: Inconsistent shrinkage leading to poorly wrapped products.

Solution: Our PET shrink film offers uniform shrinkage across the entire roll, ensuring a perfect wrap every time. Our advanced manufacturing process maintains a shrinkage variation of less than 2%, compared to the industry standard of 5-7%.

Problem: Film breaking during high-speed packaging operations.

Solution: With a tensile strength of 25,000 PSI, our PET shrink film is designed to withstand the demands of high-speed packaging lines. This results in fewer line stoppages and up to 15% increase in production efficiency.

Problem: Difficulty in finding eco-friendly packaging options.

Solution: Our PET shrink film is not only 100% recyclable but also available in options made from up to 30% post-consumer recycled content. By choosing our eco-friendly film, you can reduce your carbon footprint by up to 25% compared to virgin PET film.

Manufacturing Process: Quality You Can Trust

YF Packaging’s PET shrink film production process involves several critical steps, ensuring high-quality output suitable for various applications. Here’s an overview of the entire manufacturing process:

1. Drying of PET Resin

The process begins with drying the PET resin to remove moisture, which is crucial for preventing degradation during subsequent processing. This step typically involves:

- Vacuum drying to maintain the integrity of the resin.

- Ensuring moisture content is reduced to below 0.005%.

2. Extrusion Casting

Once dried, the PET resin is melted and extruded into thick sheets:

- The resin is heated and plasticized in an extruder.

- The molten PET is cast onto a cooling roller, forming sheets that will later be processed.

3. Biaxial Stretching

The thick sheets undergo a biaxial stretching process:

- Longitudinal stretching: The film is stretched in one direction.

- Transverse stretching: The film is then stretched in the perpendicular direction.

This step aligns the molecular structure, enhancing the film’s strength and flexibility.

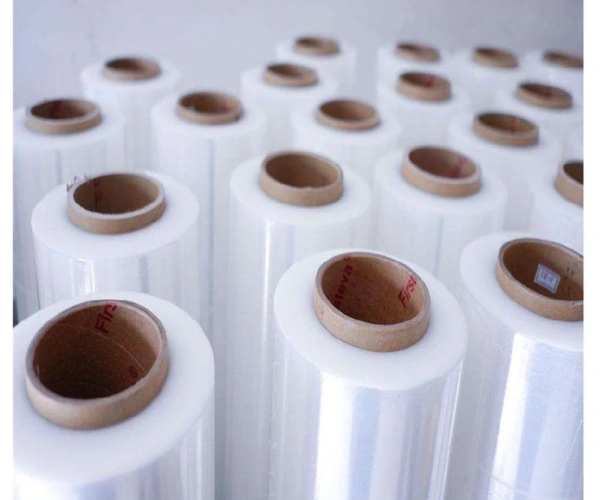

4. Winding and Slitting

After stretching, the film is wound into rolls:

- These rolls are then slit into specific widths based on customer requirements.

5. Heat Shrink Process

In the packaging phase, the PET shrink film is utilized as follows:

- The film is wrapped around products and sealed using a sealing machine.

- The wrapped products enter a heat tunnel where hot air circulates, causing the film to shrink tightly around the product.

This ensures a snug fit that protects against dust and moisture while improving visual appeal.

6. Cooling Phase

After shrinking, the packages go through a cooling phase:

- This solidifies the film around the product, ensuring durability and a polished finish.

Frequently Asked Questions

Our standard MOQ is 1,000 kg (2,205 lbs) per size and thickness. However, we understand that every business is unique. Contact us to discuss your specific needs, and we’ll do our best to accommodate you.

Most standard orders are ready to ship within 7-10 business days. Custom orders may take 14-21 business days, depending on complexity. Need it faster? Ask about our rush order options!

Absolutely! We offer high-quality flexographic printing up to 8 colors. Our printing experts will work with you to create eye-catching designs that make your products stand out on the shelf.

Yes, our PET shrink film is FDA approved for direct food contact. It’s perfect for packaging a wide range of food products, from fresh produce to baked goods.

PET shrink film offers several advantages over PVC:

- 25% stronger, reducing tears and breakage

- Wider temperature resistance range (-40°F to 149°F vs 0°F to 149°F for PVC)

- 100% recyclable, unlike PVC which is difficult to recycle

- No harmful chemicals or odors

Ready to Solve Your Packaging Challenges?

Don’t let packaging issues hinder your business. Contact Us today!